Bojiong (Shanghai) Precision Machinery Technology Co., Ltd. was founded in June 2014. It is a comprehensive operator specializing in the sales, maintenance, and research and development of precision measuring instruments, automated measurement and control equipment, machine tools, cutting lubricants, and cutting tools.Our main products including Interferometric Sensor, Wavefront Analyzer, Wavefront Sensor, 3D Cell Microscope, Machine Vision Inspection and Interference Measurement, etc.

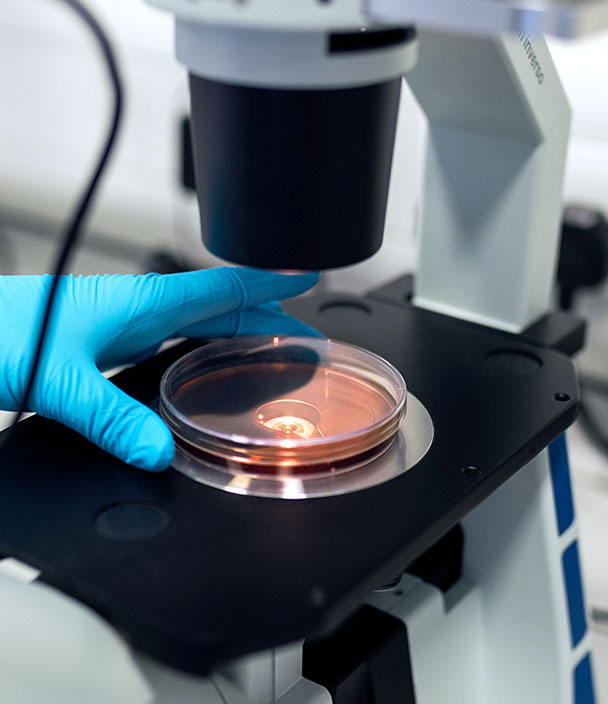

3D Cell Microscope is a marker-free real-time live cell imaging analyzer for cell incubators developed by a professional team of scientists from Zhejiang University and Nanyang Technological University in Singapore. It can run stably in the cell incubator or anoxic chamber for a long time and monitor cell growth changes in real time to restore the true cell growth state. You can rest assured to buy customized 3D Cell Microscope from us. We look forward to cooperating with you, if you want to know more, you can consult us now, we will reply to you in time!

BOJIONG 3D Cell Microscope is a live cell imaging system device designed to visualize and quantify the timing of adherent cells. It is gentle on all cell types and can be used to monitor cell lines and subtle cell types, such as induced pluripotent stem cells or primary human cell cultures. Since cell imaging using 3D Cell Microscope is stain free, label free, and harmless to the cells studied, these cells can be used for further study after imaging. It can display 3D images of cells and various micro and nano fine structures, the detection system is stable, the cell image adjustment is easy to obtain, and the biological cell biopsy can be carried out for a long time without staining and damage, with all the observation functions of conventional inverted microscope.

Advantages of 3D Cell Microscope compared to other fluorescence microscopes on the market: Observation of cells and bacteria does not require fluorescence + staining, can see the real 2D or 3D fine structure and appearance of cells, can reflect and calculate the real morphological changes of cells after drug feeding, can record cell dynamic changes and cell life cycle changes in real time, can count and weigh, direct observation accuracy reaches micron level. Create a new precision of cell detection in the industry! Applications: Cancer research, stem cell research, drug discovery and development, and in vitro wound healing validation.

BOJIONG is a professional China Interferometric Sensor Manufacturers and China Interferometric Sensor suppliers. Focus on providing high-end optical inspection and measurement equipment. With the R&D team composed of scientists from Zhejiang University and Nanyang Technological University in Singapore as the technical core, it has developed and launched products such as sub-micron defect detection series, interferometry series, intelligent size measurement series and AI intelligent deep learning series. Have strong technical support, good quality and service guarantee.

BOJIONG Interferometric Sensor has Chinese patented technology, which combines diffraction and interference to achieve a common four-wave transverse shear interference. It has super detection sensitivity and anti-vibration performance, and can achieve real-time, high-speed dynamic interferometry without vibration isolation; the real-time measurement display frame rate can reach more than 10 frames. At the same time, BOJIONG interferometric sensor has an ultra-high phase resolution of 512×512 (260,000 phase points), the measurement band covers 200nm~15μm, the measurement sensitivity reaches 2nm, and the measurement repeatability is better than 1/1000λ (RMS). The bands can be customized according to customer needs to meet the application needs of different scenarios.

BOJIONG interferometric sensor is designed to provide reliable data for optical processing companies, major universities, measurement units, researchers in scientific research institutions, and relevant personnel who write scientific papers. Single optical path interference has strong anti-vibration performance, no reference light is needed, the layout is simple, no special interference device is needed, the adjustment is quick and easy, and real-time imaging is possible without phase shifting process. It can be used in laser, optical processing, semiconductor processing, consumer electronics industries, High-precision detection in aerospace, scientific research, biomedicine and other fields.

BOJIONG specializes in the development of high-end optical interferometry and inspection equipment. It is a leading manufacturer and suppliers of wavefront sensors in China. The wavefront sensor, developed by a team of professors from Zhejiang University and Nanyang Technological University of Singapore, combines diffraction and interference to realize common four-wave transverse shear interference. Therefore, the four-wave transverse shear interferometer based on random coding hybrid grating not only has compact structure, simple instrument adjustment and stable interference fringes, but also can realize wavefront detection with arbitrary distortion. It can be used in wavefront sensing and wave aberration measurement of photographic projection objective.

BOJIONG Wavefront Sensor Variable shear rate Wavefront Sensor based on random coded hybrid grating; Based on the existing sensors, a transmission device with variable shear rate is designed. The equipment is highly integrated, the mechanism is simple, the adjustment is convenient, the measurement is flexible, the precision is high, and the universality is strengthened. Advantages of the wavefront sensor: single-path optical self-interference, no reference mirror, strong vibration resistance, no optical vibration isolation, 2nm RMS high phase resolution, simple and fast interference light path construction, support collimation beam, large NA convergence beam.

The BOJIONG Wavefront Sensor can obtain different shear rates by adjusting the forward and backward movement of the randomly coded mixed grating, so as to realize the four-wave front transverse shear interference, which can detect the transient wavefront in real time, and can detect the quantitative phase of biological cells. The continuous adjustable shear quantity enables the wavefront sensor to select the best shear rate for the specific wave front to be measured, the measurement is flexible, the measurement accuracy is high, and the universality is enhanced. Real-time dynamic detection, 3D real-time imaging, designed for optical processing enterprises, universities, units of measurement, research institutions researchers, scientific and technological paper writing personnel to provide reliable data.

BOJIONG is a leading China Machine Vision Inspection manufacturer, supplier and exporter. Have a strong technical team and after-sales service guarantee.Adhering to the pursuit of perfect quality of products, so that our Machine Vision Inspection have been satisfied by many customers. Extreme design, quality raw materials, high performance and competitive price are what every customer wants, and that's also what we can offer you. Of course, also essential is our perfect after-sales service. You can rest assured to buy customized Machine Vision Inspection from us. We look forward to cooperating with you, if you want to know more, you can consult us now, we will reply to you in time!

Machine Vision Inspection advantages: Based on circular micro-scattering dark field imaging, resolution up to 0.5μm, high and low power scanning combination, to achieve a large range of high-precision detection, macro-scale micro-defect detection, automatic planning according to the surface shape of the subaperture scanning, automatic output digital reports, compatible with national standards, military standards, international tables, statistical reports, etc. AI Deep learning is based on machine learning theory, through a hierarchical learning process that extracts high-level, complex abstractions as data representations, deep learning methods produce results faster than standard machine learning methods. It is suitable for automatic detection of appearance defects in Machine Vision Inspection.

The automatic, high-speed and high-precision detection of glass and metal surface defects can be realized by using Machine Vision Inspection, which can effectively solve the problem of low efficiency and poor accuracy of visual detection. It is suitable for the surface defect quality control of mobile phone screen, display screen, optical component, low-light component, metal product surface, silicon wafer, etc. The device can output reports automatically in the following formats: U.S.Miitary Standard MIL-PRF-13830A/B, ISO10110-7, GB/T 1185-2006. For optical components, wafer surface nanometer, sub-micron defect detection and spherical, aspherical surface defect detection at sub-micron level.